Sealed tank car

Classification

Sealed tank car

Product Introduction

The QLC5075GZX new enclosed self-unloading truck (sealed tank truck) (upper structure) is designed and manufactured according to the user's technical requirements and on-site operating conditions.

The new enclosed self-unloading truck (sealed tank truck) uses a hopper gravity discharge method for loading. The unloading port at the user's loading point is equipped with a dust removal device; the discharge method is a tank lifting and tilting self-unloading method. Both the top hopper and the rear cover have sealing strips to achieve zero-pollution closed-loop transportation, preventing material leakage and dust dispersion.

The opening and closing, and locking of the hopper cover and the rear cover are all hydraulically operated.

This new enclosed self-unloading truck (sealed tank truck) is suitable for loading and transporting non-sticky, dry, powdery granular materials. Such as sintered, ironmaking return ore, and other powdery granular materials. The material properties are as follows:

1. Material Specific Gravity: 1.5~3.0 (t/m3).

2. Maximum Material Particle Size: 5mm, Proportion <50%.

3. Material Moisture Content: <5%.

4. Material Temperature: ≤80℃.

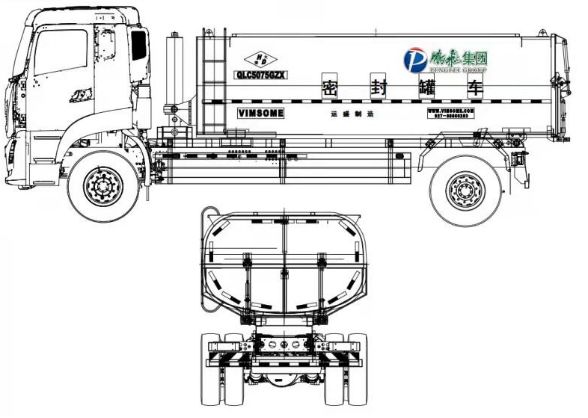

(Diagram of the new sealed tank truck)

II. Main Technical Parameters

Model | QLC5075GZX | ||

Chassis Model | Dongfeng National VI EQ1075SJ3CDF | ||

Overall Vehicle Dimensions (mm) | Length | 5700 | |

Width | 2100 | ||

Height | 2250 | ||

Wheelbase (mm) | 3308 | ||

Front overhang/Rear overhang (mm) | 1055/1337 | ||

Factory-set Maximum Gross Vehicle Weight (kg) | 7360 | ||

Maximum Payload (kg) | 3200 | ||

Maximum Speed (km/h) | 110 | ||

Tank Volume (m3) | 2.5 | ||

Maximum Tank Lifting Angle (°) | 45 | ||

Hydraulic System | System Pressure (Mpa) | 16 | |

Oil Pump Model | Yuci CBN-F550 | ||

Lifting Hydraulic Cylinder | Jia Heng 3TG118*2500 | ||

Rear Cover Hydraulic Cylinder | Chaoshun CSYG225 | ||

Top Cover Hydraulic Cylinder | Self-made | ||

Multi-way Valve | Yuci OZT-L15H-T30 | ||

Main Structure

This upper structure is installed on a Dongfeng Dollica vehicle chassis provided by Dongfeng Motor Group Co., Ltd. The upper structure includes: loading tank assembly, sub-frame assembly, rear cover assembly, top cover assembly, hydraulic system, control system, monitoring device, and the necessary mudguards, side guards, and rear guards for loading.

1. Tank Assembly

The tank has an elliptical cross-section, with a width of 1854 and a height of 947. The front of the tank is fitted with the upper support of the lifting hydraulic cylinder, and the lower rear of the tank is fitted with a tilting hinge. A 2350x1000 hopper is provided on the top of the tank for hopper gravity loading. A sealing strip is installed on the upper surface of the hopper.

A camera is installed on the top and tail of the tank to facilitate the driver's observation of the top and tail.

2. Sub-frame Assembly

The sub-frame is welded from left and right longitudinal beams and cross beams. The front is sequentially fitted with the lifting hydraulic cylinder seat and tank support pad, and the rear is fitted with the tilting shaft, etc. The sub-frame is connected to the main beam of the vehicle chassis via side ear plates or U-bolts.

3. Rear Cover Assembly

The rear cover is a semi-opening structure. The upper half of the rear end of the tank is sealed with a cover plate, and the lower half is an opening structure.

The opening and locking of the lower cover are driven by a hydraulic cylinder. When opening, the hydraulic cylinder retracts the slide part to disengage the hook (unlocking), and then completely retracts to open the rear cover. When closing, the hydraulic cylinder extends to close the rear cover first, and then pushes the adjusting rod to lock the rear cover.

The sealing strip is installed on the rear cover. When the cover is closed and locked, the sealing strip presses against the tank flange, ensuring reliable sealing.

4. Top Cover Assembly

Given the user's restriction that the vehicle's overall height does not exceed 3000mm, the top cover can only be a parallel opening type.

The top cover consists of two door panels with a length of 2430 and a width of 536. It is composed of a simple four-bar hinge mechanism, the panels are parallel to the frame, driven by a cylinder to rotate the crank, which drives the rocker to rotate, thus opening (closing) the top cover.

The opening (closing) of the top cover is driven by two cylinders.

5. Hydraulic System and Monitoring Device

The hydraulic system includes an oil pump, oil tank, three-way multi-way valve, lifting hydraulic cylinder, rear cover hydraulic cylinder, two top cover hydraulic cylinders, hydraulic lock, overflow valve, and pipe fittings, etc.

System pressure 16MPa

The operating pressure of the top cover hydraulic cylinder is controlled by the corresponding overflow valve.

6. Operation Control System

(1) Please refer to the chassis manual for chassis operation.

(2)The upper structure includes the following operations:

①Lifting, mid-stop and lowering of the tank body;

②Opening and closing of the top cover;

③Closing, locking and unlocking of the rear cover;

Note: All the above operations are controlled by the hydraulic multi-way valve.

The multi-way valve has two functions: manual lever operation and pneumatic operation. It can be operated from the ground or from the cab.

Ground operation only requires moving the corresponding lever on the multi-way valve. Cab operation requires moving the corresponding toggle switch on the control panel. The multi-way valve is operated pneumatically via a solenoid valve.

(Cab control panel)

(Multi-way valve operation sign)

Key words:

油缸

操作

罐体

液压

后盖

顶盖

物料

总成

多路

MESSAGE

Message consultation

027-88866812

027-88866812

3992538510@qq.com

3992538510@qq.com Online Message

Online Message